A Case for Integrated Box Build: Fewer Hand-offs, Fewer Headaches, Better Results

The decision between managing multiple vendors and choosing an end-to-end box build partner can make or break your timeline, budget, and quality goals. Not all costs show up on the invoice—but their effects can be costly all the same.

Increased Logistics & Shipping Costs

- • Multiple shipments between suppliers for PCBs, cables, mechanical enclosures, final assembly, etc.

- • Higher freight and handling charges (especially for fragile or high-value components).

- • Potential for delays or damage in transit.

Longer Lead Times

- • Each supplier operates on its own schedule, extending overall time-to-completion.

- • More coordination is needed to align timelines across vendors.

Quality Control Gaps

- • Variability in quality standards and inspection processes.

- • Increased likelihood of miscommunication about specs or requirements.

- • More rework, scrap, or field failures if defects aren’t caught early.

Complex Project Management

- • Extra internal resources needed to coordinate scheduling, documentation, and communication across multiple vendors.

- • Risk of misaligned priorities or misunderstandings between suppliers.

Higher Inventory Holding Costs

- • Need to buffer against delays with extra stock.

- • Managing multiple inventory streams (PCBs, cables, housings, etc.) adds overhead and complexity.

Increased Risk of Compatibility Issues

-

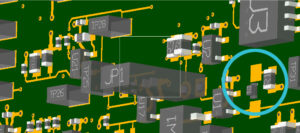

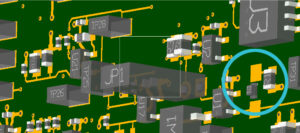

- • Mechanical and electrical mismatches due to lack of integrated DFM (Design for Manufacturability) oversight.

- • More engineering time spent troubleshooting and revalidating components.

Duplicate Administrative Effort

- • Multiple purchase orders, invoices, and vendor qualification/monitoring.

- • Extra burden on procurement and accounting departments.

Multi-Point Accountability Hampers Quick Solutions

- • Finger-pointing between suppliers when issues arise.

- • Difficult to root-cause and resolve problems quickly without a single responsible party.

Diverted Resources

- • Engineering, sourcing, and quality teams spend more time managing fragmented supply chains rather than innovating or supporting customers.

When a box build is fragmented across multiple suppliers, hidden costs mount quickly—not just in dollars, but in time, risk, and reduced responsiveness. Consolidating with a full-service contract manufacturer streamlines communication, enhances accountability, and typically lowers the Total Cost of Ownership.

#Building Tomorrow Together

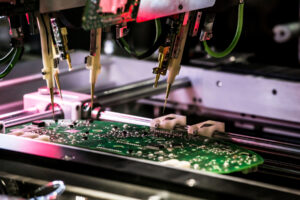

A revolutionary addition to our PCBA manufacturing equipment lineup.

A revolutionary addition to our PCBA manufacturing equipment lineup. Communication and Collaboration:

Communication and Collaboration: insight into the intricacies involved in manufacturing their designs. Designs that are complex, use specialized components, or have tight tolerances may greatly benefit from a manufacturability review. By subjecting your design to a comprehensive manufacturability analysis, you can enhance manufacturing efficiency, boost product reliability, and take advantage of cost-effective production processes.

insight into the intricacies involved in manufacturing their designs. Designs that are complex, use specialized components, or have tight tolerances may greatly benefit from a manufacturability review. By subjecting your design to a comprehensive manufacturability analysis, you can enhance manufacturing efficiency, boost product reliability, and take advantage of cost-effective production processes. Quality Control and Testing:

Quality Control and Testing: Cost Management:

Cost Management:

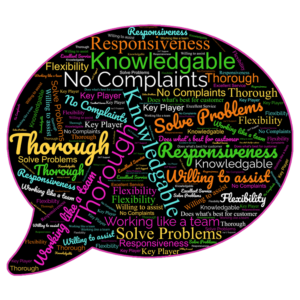

In the dynamic realm of manufacturing, the customer’s voice resonates profoundly. Altek believes in conducting regular customer satisfaction surveys and uses this information to guide our continuous improvement and innovation plans. These surveys serve as a compass, to ensure we are meeting and exceeding customer expectations.

In the dynamic realm of manufacturing, the customer’s voice resonates profoundly. Altek believes in conducting regular customer satisfaction surveys and uses this information to guide our continuous improvement and innovation plans. These surveys serve as a compass, to ensure we are meeting and exceeding customer expectations.

reliability of your finished product. Investing in DFM analysis may incur an initial cost, but the benefits of avoiding production issues far outweigh the expense of the review.

reliability of your finished product. Investing in DFM analysis may incur an initial cost, but the benefits of avoiding production issues far outweigh the expense of the review.

Highlighted below are the items Altek discusses when working with a prospective customer. Not only are these important conversations for Altek to have with its customers, but important points to consider when evaluation any Contract Manufacturer. Getting this information on the table helps determine the customer/supplier fit before proceeding with the quote process.

Highlighted below are the items Altek discusses when working with a prospective customer. Not only are these important conversations for Altek to have with its customers, but important points to consider when evaluation any Contract Manufacturer. Getting this information on the table helps determine the customer/supplier fit before proceeding with the quote process.