One of the most significant challenges that electronic designers face when sending their PCBA or Enclosure designs to a contract manufacturer (CM) is ensuring a smooth and successful transition from the design phase to the manufacturing phase. This transition involves several potential pitfalls, and managing these challenges is crucial for a successful product launch. Here are some key considerations:

Communication and Collaboration:

Communication and Collaboration:

Collaborative communication is vital to ensure that the CM understands the design requirements, specifications, and any specific considerations that could impact the final product. Contract manufacturers that have a robust “New Product Introduction Process” can reduce miscommunications resulting in a smoother transition.

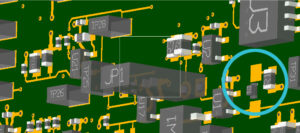

Manufacturability Analysis:

It is not uncommon for designers to have limited  insight into the intricacies involved in manufacturing their designs. Designs that are complex, use specialized components, or have tight tolerances may greatly benefit from a manufacturability review. By subjecting your design to a comprehensive manufacturability analysis, you can enhance manufacturing efficiency, boost product reliability, and take advantage of cost-effective production processes.

insight into the intricacies involved in manufacturing their designs. Designs that are complex, use specialized components, or have tight tolerances may greatly benefit from a manufacturability review. By subjecting your design to a comprehensive manufacturability analysis, you can enhance manufacturing efficiency, boost product reliability, and take advantage of cost-effective production processes.

Component Availability and Supply Chain Issues:

The availability of components in the market can be a significant concern. PCBA designers need to ensure that the components used in the design are readily available and have a positive part lifecycle. Rapid changes in component availability or sudden shortages can disrupt production schedules, increase costs and lead to schedule delays.

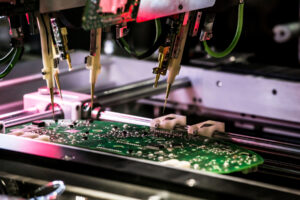

Quality Control and Testing:

Quality Control and Testing:

Maintaining consistent quality throughout the product lifecycle is of utmost importance. Partnering with a Contract Manufacturer that shares your quality standards and possesses the necessary systems and equipment ensures a harmonious alignment with your requirements. Developing clear test criteria and procedures helps identify and address potential issues before they impact the final product. Your CM’s team of Engineers can provide invaluable support in this area.

Cost Management:

Cost Management:

Balancing cost and quality is a constant challenge. PCBA designers need to work closely with their manufacturing partner to optimize the design for cost-effective production without compromising product quality. Avoid unexpected cost overruns that can impact the overall profitability of your product by involving your CM early in the process.

Intellectual Property (IP) Protection:

Protecting intellectual property is a concern when working with external manufacturers. OEMs must establish clear agreements regarding the protection of their designs, technology, and proprietary information.

Regulatory Compliance:

Ensuring that the manufactured product complies with relevant industry regulations and standards is essential. Design engineers and manufacturers must work together to navigate the landscape to meet regulatory requirements.

Timeline and Production Scheduling:

Meeting project deadlines is essential for product launches and market competitiveness. Delays in manufacturing can result in missed market opportunities.

Addressing these challenges requires a strong partnership between the OEM and Contract Manufacturer. Open communication, focus on collaboration, and attention to details throughout the design and manufacturing process are essential. Early involvement of your manufacturing partner utilizing new product introduction processes and manufacturability evaluations will ensure you are off to the best possible start!